Top 7 Heat Exchanger Failures and How to Prevent Them

Categories:News Author: author

Top 7 Heat Exchanger Failures and How to Prevent Them

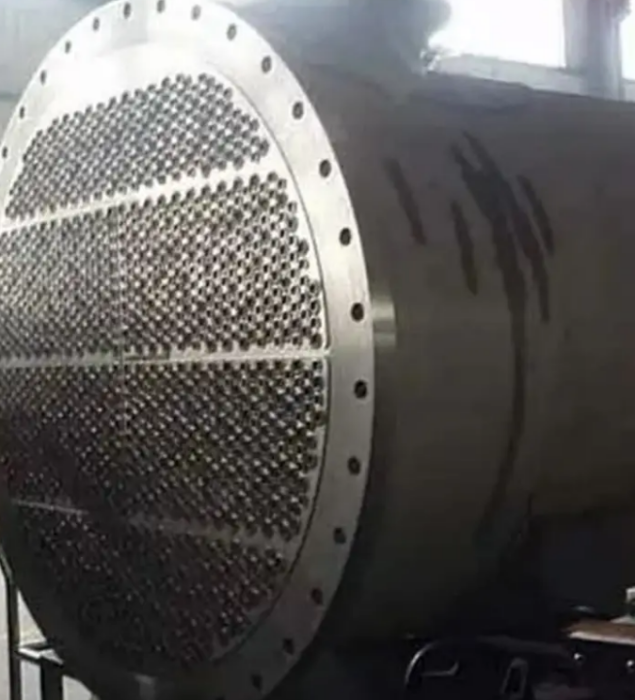

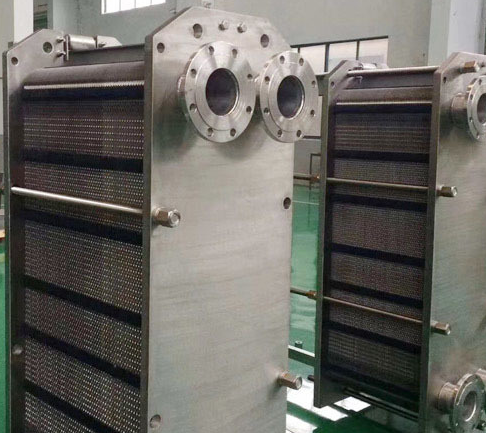

Heat exchangers, as essential and critical equipment in industrial production, are widely used in a variety of fields, including chemical, petroleum, power, metallurgy, food, and pharmaceuticals. They transfer heat, helping to achieve efficient energy utilization and optimize process flows. However, over the course of long-term operation, heat exchangers are inevitably subject to various failures. These failures not only reduce equipment efficiency and increase energy consumption, but can also lead to production stoppages or safety incidents.

This article will provide an in-depth analysis of the seven common types of heat exchanger failures and provide detailed prevention and resolution strategies. Mastering this knowledge will not only effectively extend the lifespan of heat exchangers and reduce maintenance costs, but also ensure stable and safe production.

Common Heat Exchanger Failures and Prevention Methods

1. Fouling

Failure Symptoms:

Fouling is one of the most common problems with heat exchangers. Scale, microorganisms, sediment, and corrosion products in the medium adhere to the heat exchange surface, forming one or more layers of deposits that are heat-resistant. Initial symptoms include decreased heat exchange efficiency, substandard outlet temperatures, increased pressure drop, reduced flow, and increased energy consumption. In severe cases, this can lead to flow blockage and even equipment damage.

Cause Analysis:

Water Quality Issues: Circulating water has high hardness and contains calcium and magnesium ions, which form insoluble salts such as calcium carbonate and calcium sulfate at high temperatures.

Microbial Growth: The cooling water system is not effectively sterilized, allowing algae, bacteria, and other microorganisms to proliferate, forming biosludge.

Suspended Matter and Particles: The medium contains solid particles such as silt, rust, and fibers, which accumulate in areas with low flow rates.

Corrosion Products: Metal oxides accumulate due to corrosion of the equipment itself.

Operating Conditions: High temperatures, low flow rates, and localized overheating of the medium can accelerate scaling.

Preventative Measures:

Optimize Water Treatment: Pre-treat cooling and process water through softening, filtration, deoxygenation, and sterilization to ensure water quality meets standards. Chemical treatment agents (such as corrosion inhibitors, scale inhibitors, and biocides) may be used.

Optimization: Select flow channel designs that are less prone to scaling, increase shear forces on the heat exchange surface, and avoid dead corners.

Regular Cleaning: Develop a regular physical or chemical cleaning schedule based on scaling conditions. Physical cleaning includes high-pressure water jet cleaning and mechanical scrubbing; chemical cleaning uses acid or alkali solutions to dissolve scale.

Monitoring and Control: Real-time monitoring of inlet and outlet temperatures, pressures, flow rates, and water quality parameters is performed to promptly detect signs of scaling and take appropriate action.

|

Scaling Type |

Main Components/Characteristics |

Main Causes |

Examples of Cleaning Methods |

|

Particle scaling

|

Solid particles such as sand, rust, and fibers

|

Solid impurities in the medium, low flow rate

|

Mechanical scrubbing, high-pressure water washing, and backwashing |

|

Crystal scaling

|

Inorganic salts such as calcium carbonate and calcium sulfate

|

High water hardness and high temperature crystallization

|

Acid washing (oxalic acid, citric acid, dilute hydrochloric acid, etc.) |

|

Chemical reaction scaling; |

Insoluble matter generated by reactions between media; |

Process media instability and side reactions; |

Cleaning with specific chemical solvents |

|

Corrosion and scaling

|

Metal oxides and hydroxides

|

Equipment corrosion, highly corrosive media

|

Pickling and passivation |

|

Biofouling

|

Algae, bacteria, microbial slime

|

Microbial growth in water, suitable temperature

|

Bactericide cleaning, mechanical scrubbing |

2. Corrosion

Failure Symptoms:

Chemical or electrochemical reactions occur on the surface of the heat exchanger material, leading to metal loss, perforation, and reduced strength. While difficult to detect initially, these reactions can lead to media leakage, reduced heat transfer efficiency, and even structural failure. Common types of corrosion include pitting, intergranular corrosion, galvanic corrosion, and stress corrosion cracking.

Cause Analysis:

Media Corrosiveness: The fluid being transported (such as acids, alkalis, saline solutions, and media containing chloride ions) is corrosive to the heat exchanger material.

Improper Material Selection: The heat exchanger material is incompatible with the media or has insufficient corrosion resistance. Operating Conditions: High temperature, high pressure, uneven flow rate, and localized stagnation can accelerate corrosion.

Impurities and Precipitation: Oxygen, chloride ions, and other substances in the medium can promote corrosion.

Stress Concentration: Stress concentration areas caused by design or manufacturing defects are prone to stress corrosion.

Prevention Methods:

Select Proper Materials: Based on the properties of the medium, temperature, pressure, and other parameters, choose materials with excellent corrosion resistance, such as stainless steel (304, 316L, 2205, 2507, etc.), titanium alloy, Hastelloy, etc.

Adding Corrosion Inhibitors: Adding an appropriate amount of corrosion inhibitor to the corrosive medium can slow or inhibit the corrosion reaction.

Surface Treatment: Passivation, coating, lining, and other treatments are performed on the heat exchanger surface to improve corrosion resistance.

Controlling Operating Parameters: Avoid operating at excessive temperatures or pressures, maintain uniform medium flow rates, and reduce localized accumulation.

Regular Inspection: Use non-destructive testing techniques (such as eddy current testing and ultrasonic testing) to regularly inspect for corrosion to detect and repair it promptly.

3. Leakage

Failure Symptoms:

The medium inside the heat exchanger flows from one flow channel to another (internal leakage), or from the inside of the heat exchanger to the external environment (external leakage). Internal leakage can lead to product contamination and mixing, and even affect process safety; external leakage causes medium loss, environmental pollution, and safety hazards.

Cause Analysis:

Gasket Failure: Gasket aging, damage, incorrect selection, improper installation, loose fastening bolts, or uneven stress.

Corrosion Perforation: Long-term corrosion causes perforation of heat exchange tubes, plates, or welds.

Mechanical Damage: Vibration, water hammer, pressure shock, external impact, etc. can cause cracks or damage to equipment components.

Temperature Stress: Uneven thermal expansion and contraction of materials caused by frequent starts and stops or rapid temperature fluctuations can lead to stress fatigue cracking.

Manufacturing Defects: Poor welding quality, material defects, etc.

Prevention Methods:

Select high-quality gaskets: Based on the characteristics of the medium and operating conditions, select gasket materials with excellent temperature, pressure, and corrosion resistance. Ensure proper installation and regular replacement.

Control Corrosion and Scaling: Reduce corrosion and scaling through the aforementioned methods to fundamentally eliminate leaks caused by them.

Avoid Mechanical Damage: Maintain stable operating conditions, avoid sudden starts and stops, and water hammer, and install necessary vibration damping and buffering devices.

Strict Manufacturing and Installation: Ensure that equipment manufacturing and on-site installation comply with specifications, welding quality is satisfactory, and bolt tightening is uniform.

Regular Pressure Testing and Leak Detection: Regularly perform hydraulic pressure and airtightness tests on heat exchangers, using tracers, leak detectors, and other techniques to detect minor leaks.

4. Blockage

Fault Symptoms:

The heat exchanger flow path is completely or partially blocked by solid particles, fibers, scale, biological slime, etc., resulting in a sharp drop in media flow, a significant increase in pressure drop, and a severe reduction in heat transfer efficiency. This can ultimately lead to media failure and equipment shutdown.

Cause Analysis:

High impurity content in the media: Inadequately filtered process fluids or cooling water carry a large amount of suspended solids.

Scaling: When the scale layer accumulates to a certain thickness, it can shrink or even block the flow path. Low flow rate: The medium flow rate is below the critical value, making it easy for particles to settle.

Design flaw: The heat exchanger's flow path is too narrow or has dead corners, which can easily cause particle accumulation.

Preventative measures:

Enhance medium pretreatment: Perform high-efficiency filtration on the fluid entering the heat exchanger to remove solid particles and suspended matter.

Regular cleaning: Refer to the prevention methods for scaling and perform regular physical or chemical cleaning to remove accumulated sediment.

Optimize flow rate: Ensure the heat exchanger operates within the designed flow rate range to avoid low flow rate areas.

Backwash: For certain types of heat exchangers, regular backwashing can be performed to remove loose blockages.

Selection considerations: For media prone to clogging, choose a heat exchanger with spacious flow paths, simple structure, and easy cleaning.

5. Vibration

Fault symptoms:

The heat exchanger experiences abnormal vibration during operation, which may be accompanied by noise. Long-term vibration can cause wear (fretting corrosion) between the heat exchange tubes, tube sheets, and baffles, leading to leaks and even structural damage.

Cause Analysis:

Fluid Induced Vibration (FIV): When the medium flows through the heat exchange tube bundle at high speed, vortices are formed, causing the tube bundle to vibrate.

Mechanical Vibration: Vibration generated by the connected pump, piping, or support structure is transmitted to the heat exchanger.

Resonance: The natural frequency of the heat exchanger approaches the external excitation frequency (such as the fluid vortex shedding frequency or pump speed).

Design or Manufacturing Defects: Insufficient supports, uneven tube bundle spacing, and loose components.

Preventative Measures:

Design Optimization: Conduct fluid dynamics analysis during the design phase to optimize the tube bundle arrangement, baffle spacing, and number to avoid tube bundle resonance.

Vibration Isolation: Install vibration dampers, flexible joints, or anti-vibration supports on the heat exchanger and related piping.

Flow Rate Control: Avoid excessively high medium flow rates, especially in areas prone to vortex generation.

Inspection and Tightening: Regularly inspect the tightening of the heat exchanger body and support structure to ensure all connections are secure.

Equipment Balancing: Ensure that connected rotating equipment, such as pumps and fans, is well balanced.

6. Seal Failure

Failure Symptoms:

Specifically refers to internal or external leakage caused by failure of gaskets, O-rings, seals, etc. This can manifest as dripping, seepage, or media cross-flow at the seal. This is closely related to the "leakage" failure described above, but focuses on issues with the seal itself.

Cause Analysis:

Material Aging: Long-term exposure to high temperature, high pressure, or corrosive media degrades the performance of the seal material and causes it to lose elasticity.

Improper Selection: The seal material is incompatible with the working media, or its temperature and pressure ratings are insufficient.

Improper Installation: Improper gasket positioning, uneven tightening bolt torque, scratches, or foreign matter on the sealing surface.

Exceeding Design Conditions: Short-term overpressure or overtemperature causes seals to be subjected to loads beyond their limits.

Frequent Start-Stop or Temperature Fluctuations: Repeated stress and thermal expansion and contraction of the seal accelerate fatigue.

Preventative Measures:

Strict Selection: Select the appropriate seal material and structure based on the specific operating conditions (temperature, pressure, and media type) of the heat exchanger. Proper Installation: Strictly follow the installation instructions, ensuring the sealing surfaces are clean, gaskets are properly positioned, and bolts are evenly tightened to the specified torque.

Regular Inspection and Replacement: Establish a preventive maintenance plan, regularly inspect the condition of seals, and promptly replace them when they reach the end of their service life or show signs of deterioration.

Control Operating Parameters: Avoid temperature and pressure fluctuations outside the design range.

Spare Parts Management: Maintain a stockpile of qualified seal spare parts to ensure timely replacement with genuine or equivalent quality parts.

7. Abnormal Pressure and Flow

Fault Symptoms:

The heat exchanger's inlet and outlet pressure differential is excessively large or small, causing the medium flow rate to deviate from the design value. This manifests as unstable heat transfer efficiency, difficulty in controlling the target temperature, increased or insufficient pump power consumption, and may even trigger a safety interlock shutdown.

Cause Analysis:

- Excessive pressure differential:

Flow channel blockage: Internal scaling and blockages increase fluid resistance.

Insufficient valve opening or pipeline restriction: The inlet valve is not fully open, or debris in the pipeline restricts flow.

Excessive pump outlet pressure: The delivery pump is operating abnormally.

- Pressure differential is too low:

Insufficient flow: Pump efficiency is reduced, or the inlet medium supply is insufficient.

Internal leakage: Cross-flow of the medium changes the effective flow path, reducing the pressure differential.

Bypass open: The medium bypasses the heat exchanger.

- Abnormal flow:

Pump failure: Pump wear, cavitation, motor failure, etc. lead to reduced delivery capacity.

Changes in system demand: Changes in upstream and downstream equipment operating conditions lead to changes in heat exchanger flow demand.

Valve failure: Regulating valves or shut-off valves are stuck or improperly operated.

Filter blockage: A clogged upstream filter leads to insufficient flow.

Preventative measures:

Real-time monitoring: Install pressure gauges, flow meters, temperature sensors, etc. to monitor and analyze key parameters in real time.

Regular cleaning and maintenance: Ensure the heat exchanger is clean and free of scale, and that the pipes are unobstructed.

Pump and valve maintenance: Regularly check the operating status of the pump and maintain valves to ensure they open and close properly.

System balancing: Regularly check the entire system flow to ensure all valves are in the correct position and that no unnecessary bypasses are open. Troubleshooting: Combined with other parameters (such as temperature changes), a comprehensive analysis is performed to determine whether the problem is with the heat exchanger itself or with the system.

FAQ

Q1: Is chemical cleaning necessary for heat exchanger scaling?

A1: Not necessarily. For mild scaling or particulate deposits, physical cleaning methods such as high-pressure water washing or backwashing can be tried. If the scale layer is dense and hard, or if physical methods are ineffective, chemical cleaning should be considered. When selecting a cleaning method, consider the scale layer properties, the heat exchanger material, and the compatibility of the cleaning agent.

Q2: How can I determine if a heat exchanger is leaking?

A2: Common signs of a leak include:

Internal leakage: Mixing of two media, abnormal outlet media composition, target temperature fluctuation or failure to achieve, abnormal pressure differential.

External Leakage: Liquid dripping, signs of leakage, crystallization or corrosion, or odor on the exterior of the heat exchanger.

Professional methods such as pressure testing (water pressure or air tightness) and tracer testing can accurately determine this.

Q3: What harm does heat exchanger vibration do to equipment?

A3: Long-term abnormal vibration can cause wear and corrosion between heat exchange tubes and supports, thinning the tube walls or even perforation, leading to leaks. Furthermore, vibration can accelerate structural fatigue, causing weld cracking and component loosening, seriously affecting equipment safety and service life.

Q4: What is the typical maintenance interval for a heat exchanger?

A4: The maintenance interval for a heat exchanger depends on many factors, including the media properties, operating conditions, equipment type, environmental conditions, and manufacturer recommendations. A comprehensive inspection and maintenance is generally recommended at least annually. For heat exchangers prone to scaling, corrosion, or high-load operation, the maintenance interval may need to be shortened. For example, for some tubular heat exchangers, the recommended maintenance interval is 6,000 hours or two years.

Q5: If I want to improve the efficiency of my heat exchanger, what other methods are there besides cleaning?

A5: In addition to regular cleaning to keep the heat transfer surfaces clean, you can also consider:

Optimizing operating parameters: Adjusting flow rates, inlet temperatures, and other parameters to more closely match the optimal design conditions.

Upgrading heat exchanger type or material: Selecting advanced heat exchangers with higher heat transfer efficiency or greater resistance to corrosion and scaling for specific operating conditions.

Installing filters: Performing finer filtration before the media enters the heat exchanger reduces sources of clogging and scaling.

Improving water treatment systems: Improving the quality of circulating or process water.

Optimizing heat recovery: Considering system-level heat recovery to further improve overall energy efficiency.

Conclusion

Stable and efficient operation of heat exchangers is crucial for the smooth operation of industrial production. By thoroughly understanding and proactively preventing seven common faults—scaling, corrosion, leakage, clogging, vibration, seal failure, and abnormal pressure and flow—companies can significantly reduce unplanned downtime, lower maintenance costs, and improve overall energy efficiency.

Preventive maintenance and early problem detection are key to extending the life of your heat exchanger. Choosing high-quality heat exchangers, combined with professional maintenance services, will ensure long-term reliability for your production line.

As a professional heat exchanger manufacturer, everheat is committed to providing high-performance, highly reliable heat exchange equipment and comprehensive solutions. Whether you're facing complex media corrosion issues or persistent scaling problems, our team of experts can tailor the most suitable technical solution for you.

Take action now to improve your heat exchange efficiency!

Choose Ever Heat Exchange to keep your heat exchanger in optimal working condition and create greater value for your business!