How Customized Dry Coolers Work for Your Industry

Categories:News Author: author

As a key energy-saving equipment in industrial heat exchange systems, dry coolers have been widely used in various industries in recent years. Compared with traditional wet cooling towers, they do not require water, have low maintenance costs, and are more environmentally friendly. They are especially suitable for occasions that require water conservation or strict hygiene requirements.

This article will introduce the working principle, industry application examples, and selection recommendations of dry coolers to help you understand how to efficiently apply dry coolers in your industry and improve the efficiency of your industry.

Customized Dry cooler working principle

What is a dry cooler?

A dry cooler is a device that uses air as a cooling medium to remove excess heat generated by a device or system from the liquid to achieve cooling.

As the name suggests, its "dry" feature means that it does not rely on the evaporation of water to cool down, but exchanges heat through air convection, which makes it environmentally friendly, energy-saving and low-maintenance.

What does a dry cooler consist of? A typical dry cooler mainly consists of the following parts:

- Fin tube heat exchanger: The liquid flows in the tube, and the outside of the tube is covered with aluminum fins to expand the heat exchange area.

- Blower (fan): Force air to flow through the heat exchanger to take away the heat of the liquid.

- Water pump system (such as for closed loop): Circulate hot liquid to the cooler.

- Control system: Automatically adjust the fan speed or start/stop to maintain the set temperature.

How many steps does a Customized dry cooler operate in?

There are six main steps. The following is a typical dry cooler workflow:

- Hot liquid input: High-temperature liquid, such as water or ethylene glycol, generated by equipment or process systems enters the dry cooler's heat exchanger through pipes.

- Liquid flow: This hot liquid flows through copper or stainless steel tubes, transferring heat to the metal fins on the outside of the tubes.

- Air flow: A high-power fan activates, blowing outdoor air over the fins.

- Heat transfer: Because the air temperature is typically lower than the liquid, a temperature difference forms between the fins and the air, allowing heat to be transferred from the liquid through the metal fins to the air.

- Heat removal: The heated air is discharged to the outside through ducts, while the liquid temperature decreases.

- Cooled liquid return system: The cooled liquid returns to the original system, such as molds, data servers, or compressors, for the next round of heat exchange.

Dry Coolers vs. Wet Cooling Towers

Compared to traditional wet cooling towers, dry coolers offer the following advantages:

1、They do not rely on evaporation and consume no water.

2、They do not require the addition of chemicals, thus preventing bacterial growth.

3、They are suitable for areas with limited water resources or high environmental protection requirements.

4、They are more suitable for low-temperature or winter operation environments.

What are the core advantages that make Customizeddry coolers so popular?

Energy Saving and Consumption Reduction

Dry coolers use air cooling instead of evaporative cooling, eliminating water consumption and making them particularly suitable for areas with water shortages or energy conservation priorities. Models equipped with EC variable-frequency blowers significantly reduce power consumption.

Easy Maintenance

No scaling issues, requiring no water treatment chemicals. Regular cleaning of the heat exchange fins and inspection of the blower are sufficient, significantly reducing maintenance labor and material costs.

Environmentally Friendly and Pollution-Free

No cooling tower drift or noise pollution, making them particularly suitable for hospitals, residential areas, and research parks with strict environmental and noise control requirements.

Flexible Installation and Long Service Life

Can be installed horizontally or vertically, adapting to various spatial conditions, such as rooftops, floors, and walls. High-quality fins, closed-circuit design, and intelligent control extend equipment life.

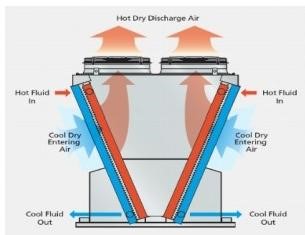

Customized Dry Cooler Types by Overall Structure

Dry coolers come in different structural configurations to suit various installation conditions. The layout impacts both footprint and heat dissipation efficiency.

| Type | Key Features | Typical Applications |

|---|---|---|

| Horizontal (Crossflow) | Stable and accessible; requires more ground space | Industrial plants, open yards |

| V-type | Compact V-shape, large heat exchange surface, balanced airflow | Rooftop units, limited space installations |

| Vertical | Compact footprint, vertical airflow | Rooftops, tight urban spaces |

How Customized Dry Coolers Work in Different Industries?

Dry coolers, due to their energy-saving, low-maintenance, and water-free properties, have replaced traditional cooling towers and other liquid cooling systems in many industries. The following is an analysis of the general applications and advantages of dry coolers in various industries:

- Manufacturing Workshops Applications: Maintaining a constant temperature for coolant in equipment such as injection molding machines, CNC machines, and die-casting machines. Advantages: Suitable for dusty, low-humidity environments, preventing scale from affecting heat exchange efficiency.

- Data Centers Applications: Cooling liquid or glycol mixtures in server cooling systems. Advantages: Combined with EC fans, they enable intelligent speed regulation, energy-saving operation, and achieve optimal year-round PUE.

- Medical Facilities & Labs Applications: Cooling precision medical equipment, air conditioning systems, and pharmaceutical refrigeration systems. Advantages: No water evaporation, high cleanliness, and suitable for environments with stringent hygiene requirements.

- Cold Chain Logistics Applications: Condensation cooling for refrigeration compressor units and high-efficiency heat exchange units. Advantages: Suitable for year-round operation, strong environmental adaptability, and extended equipment life.

- Commercial Complexes and Offices Applications: Serves as the condensing cooling terminal for air conditioning systems, paired with water-cooled screw units. Advantages: Quiet and energy-efficient, easy to install on rooftops, and reduces floor space usage.

- Automotive Manufacturing Applications: Cools welding process cooling water, test benches, mold coolants, etc. Advantages: Suitable for heavy-duty cycles and continuous high-temperature operation, improving stability.

- Industrial Parks Applications: Provides a modular solution for cooling centralized energy stations or various factory equipment. Advantages: Parallel expansion, simplified maintenance, and suitable for multi-user distributed systems.

- High-Temperature Process Environments Applications: Cools coolant in high-temperature processes such as oil refining, metal processing, and glass furnaces. Advantages: High-temperature-resistant design, equipped with a high-temperature dry cooler, ensuring system safety.

- Energy Recovery Systems Applications: Cooling circuits in waste heat recovery heat exchange stations, such as flue gas heat recovery and compressed air waste heat recovery. Advantages: Improves energy efficiency and meets environmental regulations.

- Chemical Plants Applications: Cooling reactor coolants, solvent condensation systems, heat exchange stations, etc. Advantages: Closed-loop operation eliminates cross-contamination, making it suitable for corrosive environments and high-risk processes.

How to custom a dry cooler for your industry?

Clear cooling requirements: Determining the system's heat load (kW), the type of coolant used, and the inlet and outlet temperature requirements is the first key step in selecting the cooler specifications.

Consider the installation environment: Analyze the space limitations, noise requirements, climate characteristics, etc. of the installation site.

Choose the appropriate configuration:

- Fan type: Energy-saving EC fans are suitable for systems with long operating time.

- Material selection: Copper tubes + aluminum fins or stainless steel materials should be used when corrosion protection requirements are high.

- Control system: frequency conversion speed regulation, automatic alarm, remote monitoring and other functions.

Seek professional technical support: If you are not sure how to choose, you can consult the manufacturer's engineers and provide operating data to obtain a one-to-one customized. solutionhttps://www.everheatexchanger.com/service/optimizing-heat-transfer-our-comprehensive-service-process.html

FAQ

Q1: Can dry coolers be used in high temperature or tropical areas?

A: Yes, just increase the heat exchange area appropriately according to local climate conditions or select a larger air volume fan. In tropical areas, low temperatures are usually used at night for heat dissipation and combined with a cold storage system to improve efficiency.

Q2: Are dry coolers suitable replacements for cooling towers?

A: In applications where the cooling water temperature must be no less than 5-10°C below the ambient temperature, dry coolers can completely replace cooling towers. They are also easier to maintain and more environmentally friendly.

Q3: Do dry coolers require regular maintenance?

A: Yes, but infrequently. We recommend cleaning the heat exchange fins and checking the fan and electronic control components quarterly.

Q4: Is it noisy during operation?

A: Conventional fans generate some noise during operation, but this can be effectively controlled by selecting a low-noise fan or installing a soundproofing cover.

Q5: Will it freeze and crack in winter?

A: When used in cold regions, an antifreeze design should be selected and antifreeze should be added to prevent damage from freezing.

Q6: Does a dry cooler require a long installation period?

A: Compared to complex wet cooling systems, dry coolers are faster to install, and standard models can generally be deployed on-site within 3-5 days.

Q8: What is the lifespan of a dry cooler?

A: The typical lifespan is 10-15 years. With regular maintenance and corrosion-resistant construction, the lifespan can reach 20 years or even longer.

Why choose customized Dry Coolers?

With increasingly stringent environmental protection policies and growing corporate energy-saving awareness, dry coolers are becoming the preferred heat dissipation solution for an increasing number of industrial systems. Their high efficiency, environmental friendliness, and maintenance-free nature make them particularly suitable for industries with stringent requirements for stability and cost control.

Foshan Ever Heat Exchanger Co., Ltd. is a high-tech enterprise specializing in the research and development, production, sales, and service of heat exchange systems for various industries. Our team has over a decade of industry experience and a deep understanding of the application requirements of diverse market segments. Leveraging this extensive experience, we provide customers with customized, efficient heat exchange solutions and related products.

If you're looking for a customized dry cooling solution for your facility or project, please feel free to contact us. Our technical team will provide expert selection and technical support.