Surface Coating Technology for EVER HEAT Heat Exchangers

Categories:News Author: author

EVER HEAT Surface Coating Technology for #HeatExchangers

#ElectrophoreticCoating | #NanoCoating | #EpoxyCoating

At EVER HEAT, we are committed to pushing the boundaries of durability, efficiency, and performance in every heat exchanger we manufacture. A critical part of that promise lies in our advanced surface treatment technologies, designed to meet the toughest environmental challenges.

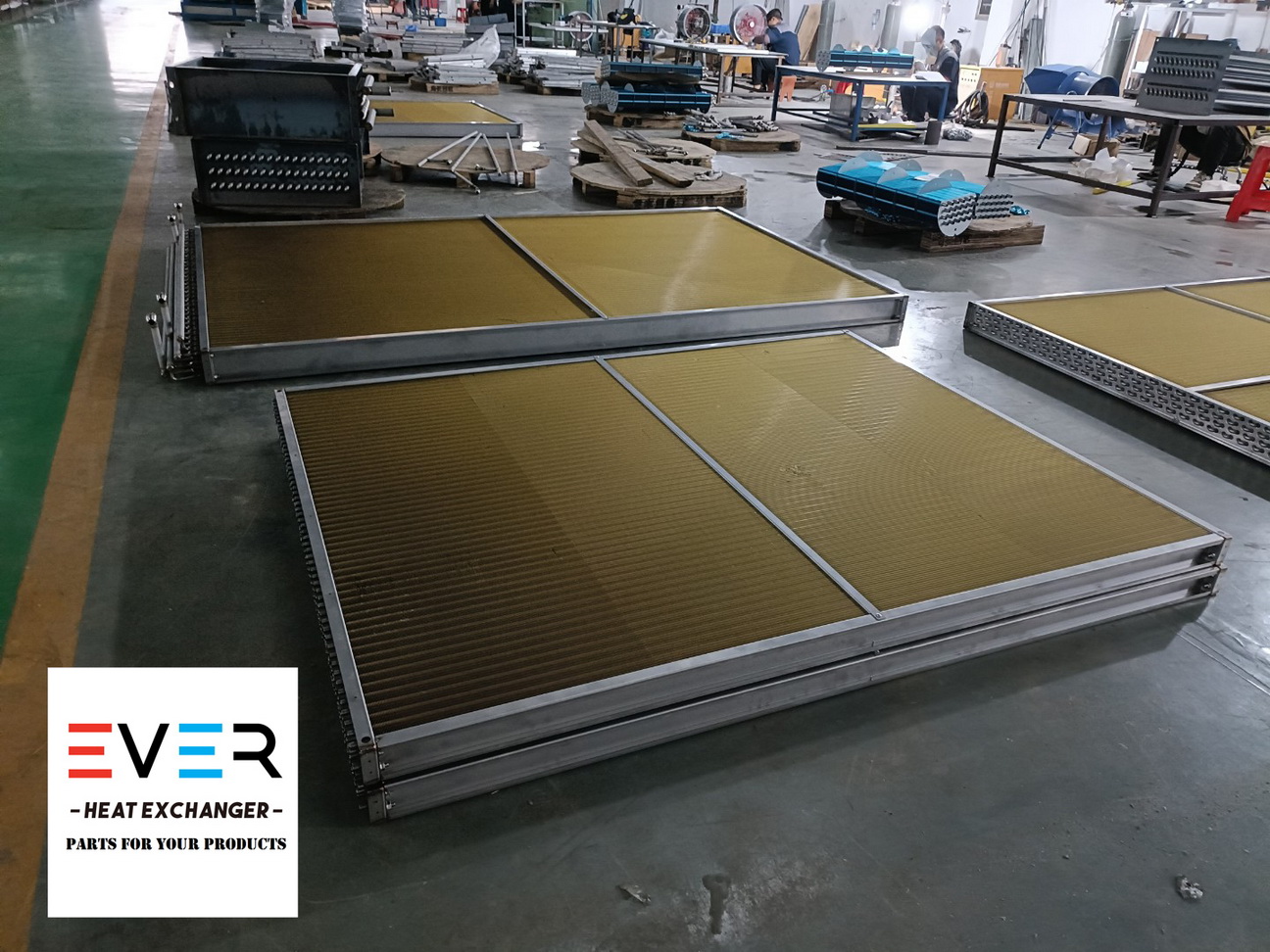

The images above showcase finished units in our workshop, fully equipped with cutting-edge coatings to ensure long-term corrosion resistance and reliability.

✅ Electrophoretic Coating (E-Coating)

Electrophoretic coating is one of the most widely used anti-corrosion technologies in our production line. It forms a uniform and strong protective film even in complex fin-tube structures.

Features:

Uniform coverage, including deep fin gaps

Strong adhesion and excellent anti-corrosion performance

Salt spray resistance > 1000 hours

Environmentally friendly, RoHS compliant

Widely used in #HVACcoils, #condensers, and #evaporators

✅ Nano Coating

Our nano-coating technology provides an ultra-thin, invisible barrier that protects against water, dust, and contaminants while maintaining heat transfer efficiency.

Advantages:

Super hydrophobic: water contact angle > 120°

Self-cleaning and anti-fouling

Does not affect thermal conductivity

Ideal for coastal or dusty environments

FDA-safe variants available for food & medical applications

✅ Epoxy Resin Coating

The epoxy coating is a cost-effective and powerful corrosion-resistant solution. Applied via spray or immersion, it delivers a durable protective layer over metal surfaces.

Applications:

Anti-acid and anti-salt spray environments

Coastal HVAC systems and industrial cooling units

Customized in various colors (commonly black, brown, grey)

Thickness: 20–50μm

Salt spray resistance > 1000 hours (ASTM B117)

💡 Why Choose EVER HEAT Coating Solutions?

In-house coating lines ensure full quality control

Customizable coating solutions to match operating conditions

Proven reliability in marine, desert, industrial, and tropical environments

Enhanced product lifespan and reduced maintenance costs

📍Pictured Above:

Our latest batch of custom finned heat exchangers coated with high-performance treatments, ready for shipment to demanding overseas markets. Every detail reflects our dedication to quality and innovation.