Stainless Steel Wound Fin Heat Exchanger Solutions by EVER HEAT

Categories:News Author: author

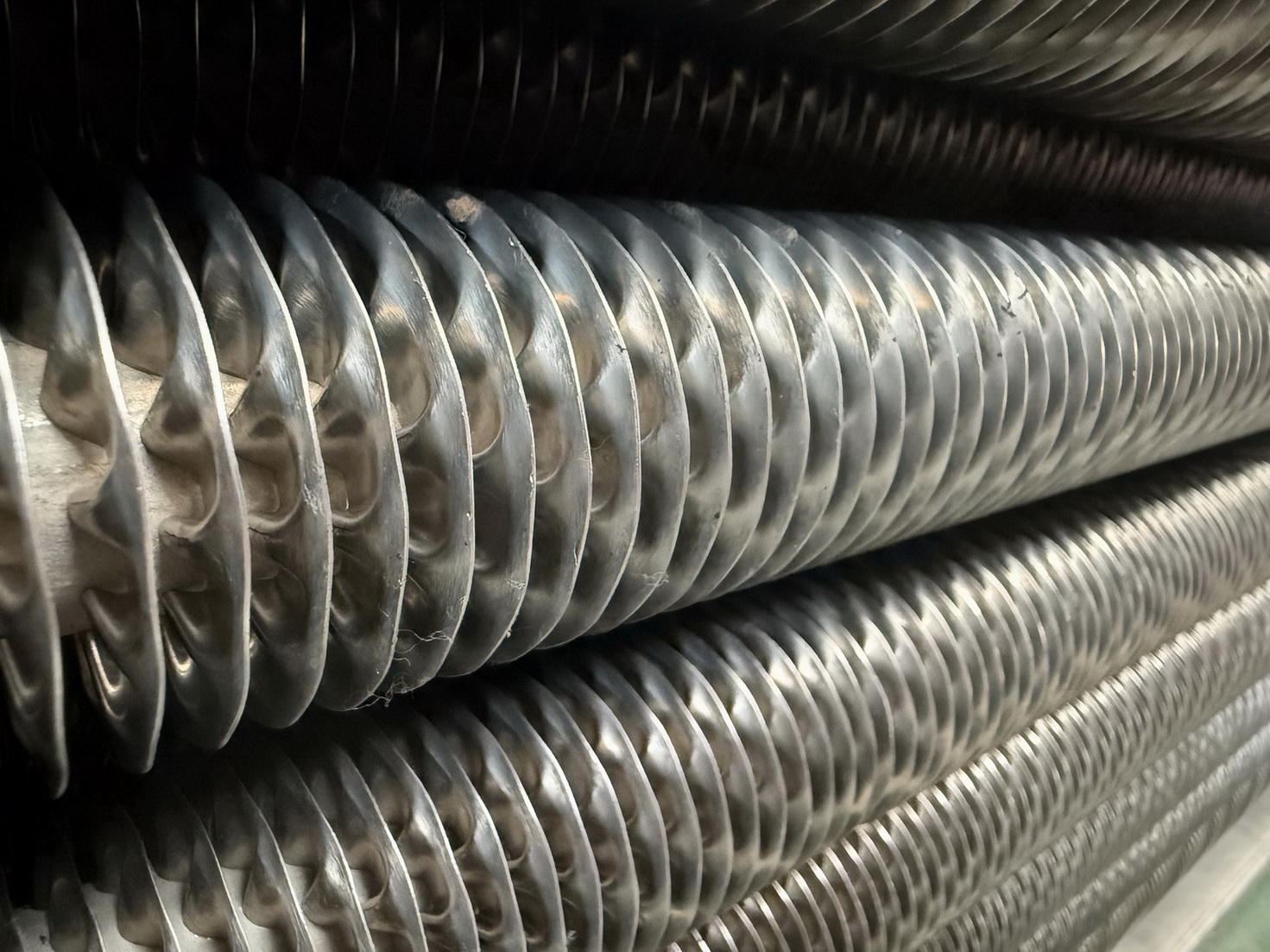

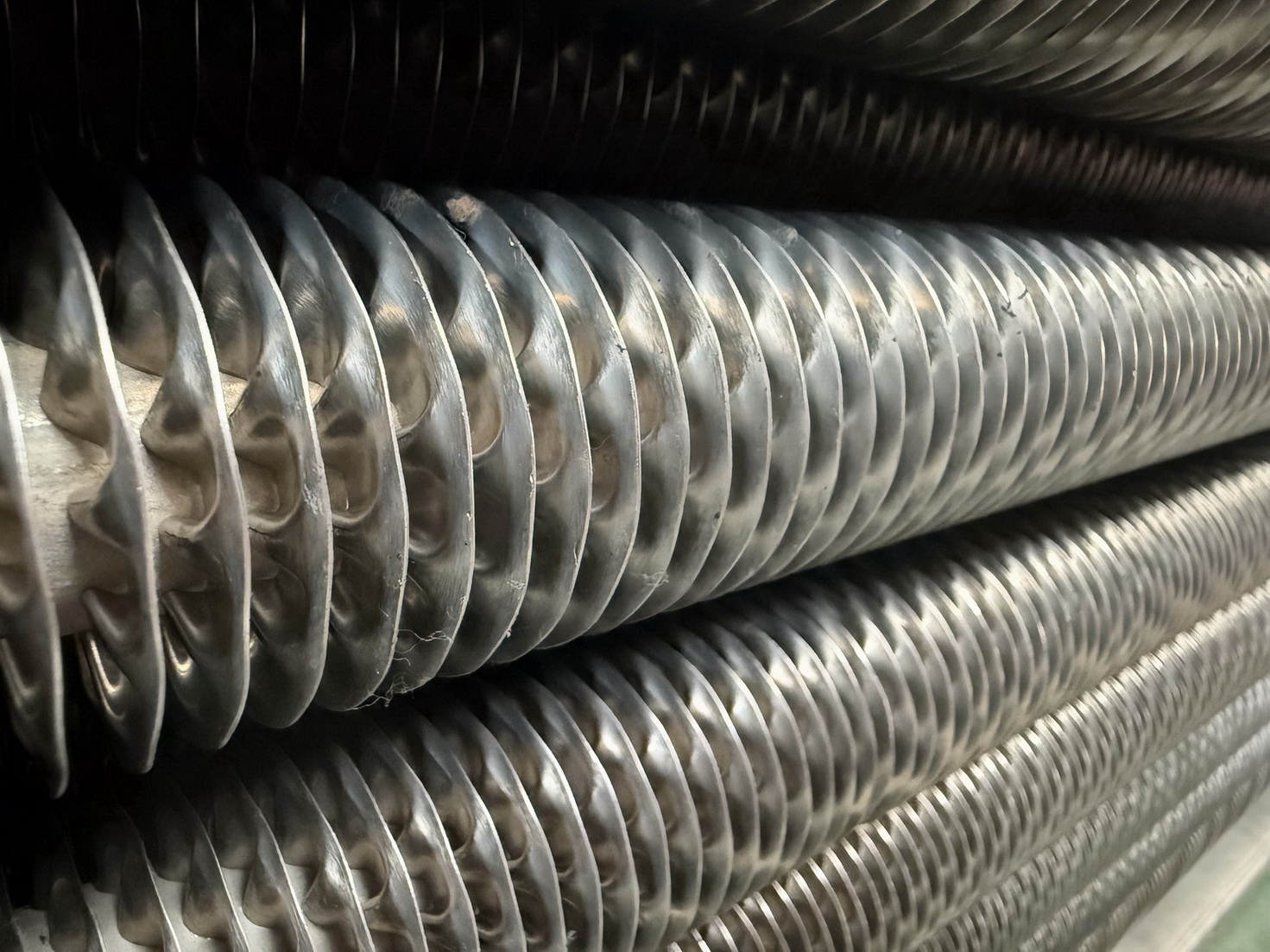

Stainless Steel Wound Fin Heat Exchanger Solutions by EVER HEAT

At EVER HEAT, we specialize in engineering high-performance stainless steel wound fin heat exchangers designed for demanding industrial and HVAC applications. With decades of manufacturing experience in finned tube technology, our stainless steel wound fin coils deliver excellent thermal performance, mechanical strength, and unparalleled resistance to corrosion—making them ideal for harsh and high-moisture environments.

Why Stainless Steel Wound Fin Technology Matters

A stainless steel wound fin heat exchanger is built by tightly wrapping stainless steel fins around a stainless steel tube, creating a strong metallurgical bond. This design significantly increases surface area, improves heat transfer efficiency, and ensures durability under extreme operating conditions.

Compared with aluminum or copper-based coils, stainless steel offers outstanding benefits:

Superior corrosion resistance for chemical plants, coastal regions, and corrosive exhaust systems

High structural strength under thermal cycling and high operating pressures

Longer service life with minimal maintenance

Stable performance under high temperature and humidity

These advantages make stainless steel wound fin heat exchangers the preferred solution for industries where reliability and long-term durability are essential.

EVER HEAT’s Stainless Steel Fin Tube Engineering

Our wound fin products are manufactured using high-precision equipment that ensures perfect fin tension, fin pitch consistency, and full surface contact between the stainless steel fin and stainless steel tube. This guarantees excellent heat transfer efficiency even in continuous or heavy-duty operation.

Key engineering features include:

Stainless Steel Fin Material: SS304 / SS316 / SS321 for corrosion-critical environments

Stainless Steel Tube Material: Seamless SS304 / SS316 tubing

Precise Fin Winding Technology: Uniform spiral winding to maximize thermal efficiency

High temperature tolerance: Suitable for flue gas, dryers, heaters, and energy systems

Custom dimensions: Tube OD, fin height, fin thickness, and fin spacing fully customizable

EVER HEAT is recognized as a trusted wound fin heat exchanger manufacturer, serving OEM clients in HVAC, petrochemical processing, energy systems, and industrial cooling.

Applications of Stainless Steel Wound Fin Heat Exchangers

Our stainless steel wound fin heat exchangers are widely used in:

Industrial dryers and heaters

Exhaust gas heat recovery systems

Chemical plant cooling and heating loops

Offshore and marine HVAC equipment

Energy and power generation systems

High-humidity and corrosive air handling units

The combination of stainless steel fin and tube construction ensures long-term reliability where aluminum or copper coils fail prematurely.

Why Choose EVER HEAT

EVER HEAT stands out in the finned tube and heat exchanger industry due to:

Advanced fin winding technology ensuring maximum heat transfer

Strict quality control at every manufacturing stage

Customized design capability to meet project-specific requirements

Rapid production and stable global supply

Expert engineering support for industrial and HVAC applications

Our mission is simple:

To deliver heat transfer solutions that outperform, outlast, and exceed industry expectations.

Conclusion

A stainless steel wound fin heat exchanger offers a powerful combination of durability, corrosion resistance, and high performance. At EVER HEAT, we continue to innovate in finned tube manufacturing, providing reliable and efficient solutions for the world’s most challenging heat transfer environments.

For customized stainless steel fin tube or wound fin heat exchangers, contact EVER HEAT — where engineering precision meets long-term reliability.