Why EVER HEAT Applies Electrophoretic Coating to Condensers

Categories:News Author: author

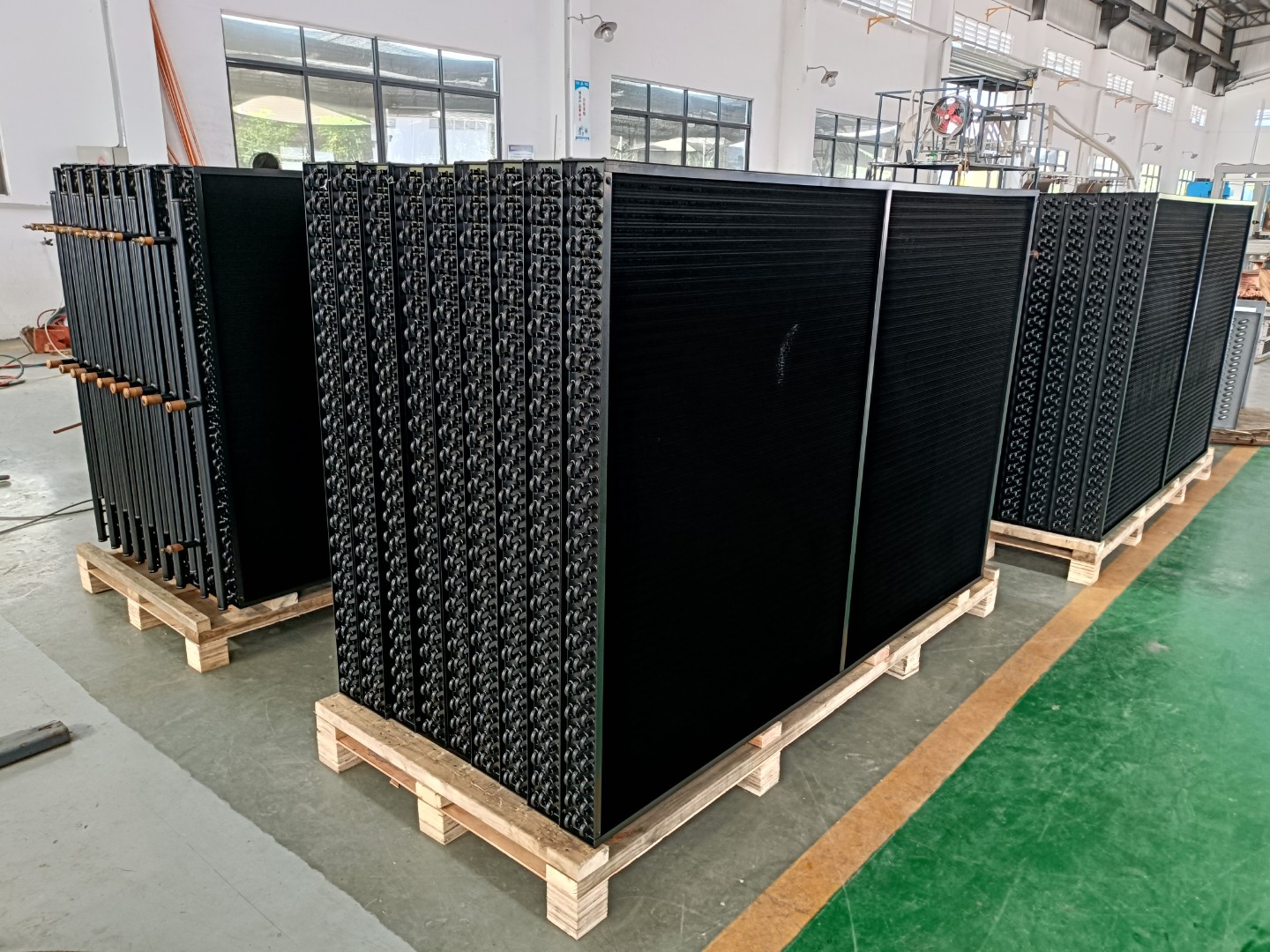

Why EVER HEAT Applies Electrophoretic Coating (E-Coating) to Condensers

Engineered Protection. Extended Lifespan. Proven Performance.

At EVER HEAT, every condenser is built for durability, reliability, and long-term performance—even in the world’s most demanding cooling environments. That’s why we apply epoxy electrophoretic coating (E-Coating) to our condenser coils and tubes.

This advanced surface treatment forms a dense, uniform, corrosion-resistant protective film, dramatically enhancing resistance against water, chemicals, and harsh atmospheric conditions.

✓ The Core Benefits of EVER HEAT E-Coating

1. Complete & Uniform Coverage

Our cathodic electrophoretic process guarantees that every part of the metal tube—internal passages, corners, edges, and hidden areas—is evenly coated. This eliminates weak spots and ensures full protection where traditional spray coatings cannot reach.

2. Exceptional Anti-Corrosion Performance

The cured epoxy film isolates the metal surface from chlorides, oxygen, and contaminants, preventing electrochemical corrosion. Whether the system uses river water, seawater, or treated cooling water, EVER HEAT condensers stay protected.

3. Strong Adhesion & Mechanical Durability

E-coating forms a highly bonded layer that resists peeling, impact, water flow abrasion, and particle erosion. This increases coil lifespan—especially in industrial and marine applications.

4. Improved Heat Transfer Stability

The smooth black coating reduces fouling, scale buildup, and microorganism attachment. As a result:

-

Heat exchanger efficiency remains stable

-

Cleaning cycles are minimized

-

System operating cost is reduced

Why It Matters — The Problems E-Coating Prevents

Without protection, condenser tubes can suffer from:

-

Uniform corrosion

-

Pitting & perforation

-

Galvanic corrosion between dissimilar metals

-

Stress corrosion cracking

EVER HEAT’s E-Coating acts as a reliable “protective armor,” preventing premature failures and costly downtime.

High-Standard Coating Quality You Can Trust

Our epoxy e-coat meets the U.S. YORK industry standard, offering:

-

Epoxy electro-deposited coating

-

Coating thickness below 0.001 inch (≈25 μm)

-

Black semi-gloss finish

-

Superior corrosion protection for extended service life

This makes EVER HEAT condensers ideal for:

-

Central HVAC systems

-

Power plants

-

Industrial cooling systems

-

Marine & offshore environments

-

High-humidity or high-salt regions

EVER HEAT — Built for Long-Term Reliability

E-Coating is not just a process step. It is our commitment to delivering long-lasting, trouble-free cooling equipment that reduces your total cost of ownership.

Stronger protection. Longer life. Higher value.

That’s the EVER HEAT standard.

#EverHeat #HeatExchanger #ECoating #CorrosionProtection #HVAC #CoolingTechnology